creating a regenerative and self-sustaining future using the power of water and light

REGENERATIVE CORE TECH FOR WATER/POWER/WASTE

A NEW PLATFORM OF CIVIL-INDUSTRIAL INFRASTRUCTURE

Scientifically advanced, 100%-regenerative proprietary core technology solutions by Langenburg Research for applications in heavy industry and civil utility infrastructure. Municipal-scale applications include municipal water / baseload grid power / waste conversion & recycling / waterworks / zero-emission hydrogen-based operation / multi-materials processing / desalination / reclamation mining.

The first and only quantum-based, scalable, modular, closed-cycle systems enabling self-sufficient municipal infrastructure – available for use, to solve the most difficult and complex challenges for any industrial process.

Shown below – Langenburg is developing the model for the first self-sustaining regenerative cities zoned for space age use.

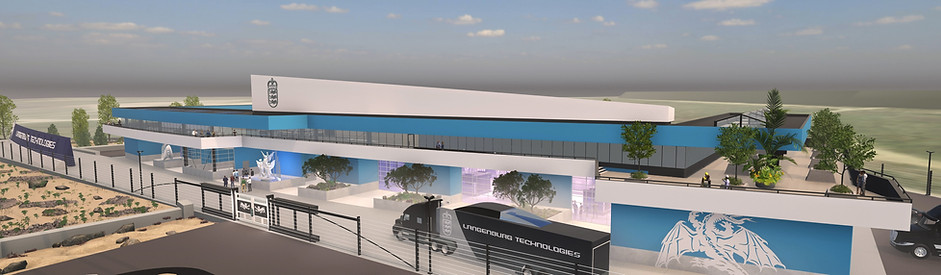

3D-ARCHVIZ CONCEPT DESIGN FOR THE LANGENBURG-COLUMBIA DEVELOPMENT PROJECT

Applications in the area of bio-regenerative and stem-cell solutions

are included in the Langenburg Research portfolio – used for integrative medical spa settings.

The most scientifically advanced suite of core technology solutions for fast and direct conversion of any waste into clean energy without residuals, for municipal water treatment/purification, and for gigawatt-capacity baseload grid power generation capable of robust load-following with immunity to electromagnetic pulse (EMP). Langenburg's proprietary power generation turbines run using its proprietary hydrogen-based noncarbon fuel, an emission-free energy source produced exclusively from any waste.

Systems are configurable to any global standard, and operate at the highest specifications available as a self-sufficient and closed-cycle system.

The above presentation highlights elements of the Langenburg-Columbia master plan, using applications Langenburg's proprietary core tech solutions for its infrastructure – all of its municipal utility systems will operate on a self-sustaining basis to recycle any waste materials and its sewage without emissions or residuals.

For cities near saltwater sources, systems can be configured to desalinate seawater while capturing medical-grade mineral salts, or to convert all or part of the dissolved content for energy production. The water component of any waste slurry is separated, purified and used for municipal water supply. This process replaces conventional water/sewage treatment plants, with the added value of converting 100% of the waste as a reclaimed resource to produce energy required the plant's operation, with excess to distribute to a large city.

Langenburg's proprietary core tech is a new industrial process that does not resemble, use or depend on conventional thermodynamic systems to work. No filtration, heat, distillation, or any other chemical processes or other input work functions are used to convert the intake. No plasma-arc, electrolysis, reverse-osmosis, mechanical separation, pyrolysis, catalysts, hydrogen extraction, or Fischer-Tropsch processes are utilized in Langenburg Systems.

APPLICATIONS FOR CIVIL INFRASTRUCTURE

& HEAVY INDUSTRY

SYSTEMS FOR WASTE CONVERSION, WATER SEPARATION,

FUEL SYNTHESIS & GRID POWER GENERATION

Langenburg Systems are modular, configurable, scalable and globally compliant for any industrial/civil infrastructure application. Shown below are systems that were fabricated, configured and programmed at Langenburg global headquarters in Eugene, Oregon USA. Larger scale systems utilize affiliated manufacturing partners.

TYPICAL COMPONENT LINE FOR A LANGENBURG WASTE-TO-ENERGY PLANT

(click below image for details )

LANGENBURG PROPRIETARY COMPONENTS

Intake Converter > Fuel Synthesizer > Turbine > Generator > Converter

TYPICAL POWER SUBSTATION COMPONENTS

Voltage Transformer > Current Transformer > Breaker > Power Grid

APPLICATIONS FOR BIOREGENERATIVE MEDICAL SPA

EQUIPMENT FOR MEDICAL BIO-REGENERATION

Advanced technologies for bio-regenerative engineering & integrative medical arts. Shown below are systems designed, fabricated and programmed at Langenburg Headquarters USA tech staging facility, to be used by our new flagship medical spa currently under construction.

See more in the VIDEO section of this website – BioRegenerative Spa

VIDEO

DEMONSTRATIONS & TESTS

CAPABILITIES OF MOBILE WASTE-TO-ENERGY & WATERWORKS PLANT

A chemical survey verified wastewater intake components including salt, iodine, coal, fly ash, steel mill slag, coal power plant ash, all rendered non-detectible by lab tests. Premium drinking water was separated from the slurry. The byproduct concentrate was converted into fuel used to operate the turbine engine.

A power quality survey verified 1 MW produced by a Langenburg proprietary onboard the trailered system. Synthetic hydrogen-based fuel used to operate it's turbine-generator power unit, was made only from tapwater. Test protocols introducing and dropping electrical loads, would destroy a conventional generator.

2016 Wastewater Conversion Demo

2014 Power Quality Survey/Demo

"BLUE TRUCK" MOBILE SYSTEM

DEVELOPMENT, TESTING, DEMONSTRATION & DEPLOYMENT

This is the latest mobile apparatus built at Langenburg's headquarters in Eugene, Oregon USA. The system will be connected to existing Langenburg equipment operating since 2019 at Langenburg's Cordele, Georgia facility. Tours resume late-2024 while entering its next phase.

DEMONSTRATION

A MOBILE WASTE-TO-ENERGY & WATERWORKS PLANT

Industrial wastewater provided by guests containing an unknown mixture of contaminants. Premium drinking water was separated from the slurry. The byproducts of the remaining concentrate was eliminated without any leftover residuals.

Mobile Waste-to-Energy System

2014 Wastewater Conversion Demo

LANGENBURG FACILITY IN GEORGIA – OPERATING SINCE 2019

LANGENBURG INSTALLATION AT A SOLID WASTE & BEVERAGE WASTEWATER RECYCLING FACILITY

Ongoing operations since 2019 – Langenburg systems separates pure water component from a beverage wastewater, converting the leftover concentrate to fuel that operates steam boilers. Steam is used to distill ethanol from a fermented re-brew of mixed beverage wastewater. Upgraded boilers will be installed producing enough excess steam to also operate a future steam turbine-generator to produce power for transmission from a grid substation located less than one mile from the site. This recycling plant also handles a variety of solid wastes, and is positioned adjacent to a landfill.

Aquarius Medical Spa

Dr. Todd Ovokaitys Interview with Max Langenburg

Equipment – LT Georgia Facility

About the LT Georgia Facility

AQUARIUS MEDICAL SPA

QUANTUM BIO-REGENERATIVE ENGINEERING & INTEGRATIVE MEDICAL ARTS

Applications of core technology developed by Langenburg Research utilizing exotic properties of light, water and other advanced technologies to activate bioregeneration for all tissue groups in the body. The BioRegenerative Equipment Room video (left) provides an overview and orientation. The BioRegenerative Stem Cell video (right) is an interview between Dr. Max Langenburg and Dr. Todd Ovokaitys discussing Very Small Embryonic-Like Stem Cell therapy using a patented photoacoustic "quantum information"(QI Laser) to activate and manage stem cell activity –

a stem cell innovation recently deemed worthy in consideration for the next Nobel Prize in Medicine.

BioRegenerative Spa

PhotoAcoustics & VSEL Stem Cells

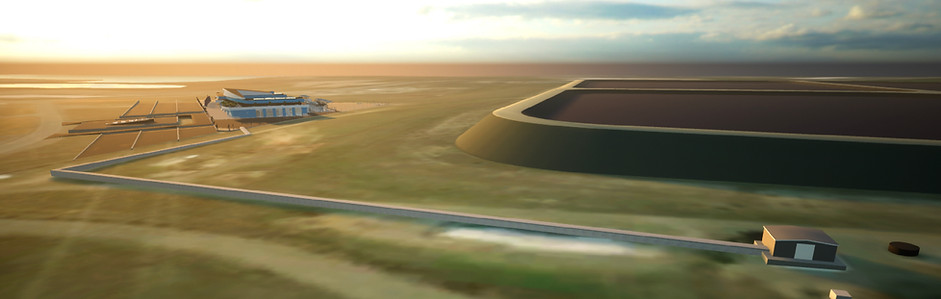

LANGENBURG-COLUMBIA DEVELOPMENT PROJECT

SPACE-AGE SELF-SUFFICIENT CITY & AIRPORT WITH REGENERATIVE INDUSTRIAL & CIVIL INFRASTRUCTURE

Strategically positioned in the region of Morrow County OR, USA near The Port of Morrow on Columbia RiverMile 270. The first power plant of the development is currently under construction in Boardman, OR. Langenburg will provide water, power, waste, and fuels for the commercial, residential, and port development, including the expansion of the existing M50 Airfield into the Langenburg-Columbia International Airport.

Modern Design Overview

Self-Sufficient City Project

THEMED OVERVIEW PRESENTATION

Themed Overview

CORE TECHNOLOGY

a quantum synergy of the power of water, and the power of light

LANGENBURG CORE-TECH SOLUTION™

Langenburg Technologies offers technology accelerator services that are applications of core technology solutions developed by Langenubrg Research... a suite of breakthrough-class technologies based upon proprietary quantum-biohydrodynamics that leverage exotic properties of The Power of Water™ with The Power of Light™ to provide comprehensive solutions for waste-to-energy conversion. The systems also produce pure water for municipal supply or bottling, including alternatives to seawater desalination – see also below "Example Applications".

The proprietary core tech process will hydrodynamically separate pure water from any liquid waste intake, converting the residual concentrates into a proprietary hydrogen-based noncarbon, and emission-free fuel. The Langenburg proprietary fuel system converts waste into a throughput fuel used within the system to operate its proprietary closed-cycle regenerative turbines (not Brayton or Heat Cycle) on the Langenburg Regenerative Energy Cycle. Langenburg proprietary power units represent a new Hydrogen-Electric power generation platform.

The Langenburg proprietary electrical generator produces electrical power based upon a regenerative quantum-electrodynamic cycle. Its capability and performance specifications are not physically possible from conventional magnetic induction generators. The proprietary power units comprise a close-cycle regenerative hydrogen turbine connected to a regenerative quantum-electrodynamic generator that is immune from electromagnetic pulse or stray radio frequency signals. Langenburg proprietary power units feature adjustable baseload output levels, and peak-power with highly robust electrical load-following ~ fully operational to baseload from black start within one minute.

APPLICATION OF HIGHLY ADVANCED SCIENCES

Combining aspects of highly advanced physics, engineering, biochemistry, quantum field, quantum-electrochemistry, quantum-biohydrodynamics, quantum-electrodynamics, and with the many exotic properties of water and light... emerges a new core technology solution for heavy industriy global civil infrastructure. Langenburg Research has developed methods and processes to manipulate and convert matter in ways not possible by classical thermodynamic systems alone. Langenburg Core Tech™ is a completely new framework of applied physics for matter-to-energy conversion, and also for materials isolation and formulation. Langenburg Systems achieve the highest specification available for heavy industry and civil infrastructure that is truly self-sustaining, far beyond what is typically considered "green" or "sustainable".

FUNCTIONS INTEGRATION ABSTRACT

(labels match the Functions Schematic Diagram and Functions Outline below)

%20220705.png)

Above Functions Integration Abstract and tagline: " Langenburg – The Power of Water™ ", and The Power of Water theme image is ©2024 Langenburg Technologies/Research.

All rights reserved & subject to Langenburg Media Use Policy.

SOME EXAMPLE APPLICATIONS

Gigawatt-capacity baseload power production for the consumer power grid;

remediation of any waste, toxic and hazmat material;

salt (and mixed-component) extraction from seawater and industrial brines;

carbon-free fuel for steam-turbine power plants, also for diesel piston engines and jet-turbine engines;

water extraction from sewage in which the component byproduct slurry is converted to fuel & power;

upgrades to recycling plants such as those that use pyrolysis, where thermal processes are either upgraded and/or replaced by the Langenburg conversion process;

co-generative power plants in which Langenburg hydrogen-based fuel qualifies as the "bottoming cycle".

Ask about other possible operational models and applications of Langenburg Technology Accelerator Services by submitting a Return Contact Request form, or a Project Inquiry Form on the Project Proposals page of this website.

INPUTS

mixed solids (converted to mixed liquid slurry)

mixed liquids (main system intake)

atmospheric air (supplemental system intake)

OUTPUTS

purified potable water for municipal tap supply

oxygenated premium drinking water for bottling

highly oxygenated medical-grade water

nutrient enriched, oxygenated farm irrigation and aquaponics water

non-carbon synthetic hydrogen-based fuel for emission-free turbine operations

hi-performance baseload power, peak power and load-following for the consumer electrical grid

configurable material formulations and separated isolates

FUNCTIONS SCHEMATIC DIAGRAM

(labels match the Functions integration Abstract above, and the Functions Outline following)

Above Functions Diagram and tagline: " Langenburg –The Power of Water™ " is ©2024 Langenburg Technologies/Research.

All rights reserved & subject to Langenburg Media Use Policy. USE WITHOUT EXPRESS PERMISSION FROM LANGENBURG RESEARCH IS PROHIBITED.

ABOUT THE NEW TECHNOLOGY PLATFORM

Applications of Langenburg Solutions represent a new platform of

waste-to-energy & waterworks technology.

Its service provisions represent the highest global performance specification for water, power and waste infrastructure – enabled by exotic quantum properties of

The Power of Water, and The Power of Light.

EQUIPMENT BUILT AT LANGENBURG USA HEADQUARTERS

FUNCTIONS OUTLINE

Terminology used in this Functions Outline, correlates with the Functions Schematic Diagram, and the Systems Integration Abstract above.

INTAKE PROCESSING

~ accepts and processes any liquid intake

~ compatible with any water or liquid intake constituent

~ compatible with particulates up to ~1/4” diameter

~ scalable to millions gal/d capacity

~ alternative to conventional desalination & water treatment

~ alternative to conventional recycling plants

/ SOLIDS REDUCTION (optional)

~ prepares mixed solid waste for slurrification

~ allows solids to be processed by the system as a liquid

~ configurable for a broad range of sizes

~ mixes liquid and solid intakes together for processing

/ CONSTITUENT ANALYTICS

~ identifies intake liquid and constituents in real-time

~ provides feedback for system’s master controller

/ BULK WATER EXTRACTION

~ separates and extracts bulk water from liquid intake

~ isolates constituents from bulk extracted water

~ routes separated water to water production system

~ routes isolated constituent mixture to be reformed

~ renders constituents as non-detectible in extracted water

/ REFORMATION

~ converts all intake constituents into aqueous solution

~ reforms completely, without residuals and byproducts

~ routes aqueous solution for synthesis of fuel

~ accepts salts from seawater and industrial brines

~ utilizes the atmosphere to assist reformation process

~ interfaces with the gas processing system

WATER PRODUCTION

~ accepts water extracted by the system

~ alternative to, & upgrade for conventional treatment plants

~ alternative to, & upgrade for hydroponic & aquaponic farms

/ TREATMENT & CONDITIONING

~ produces potable, municipal supply & tap water

~ treats water by sanitization & restructuring

~ removes septics and coliform

~ conditions water by re-mineralizing

~ oxygenates water for premium drinking & bottling

~ mineralizes water to optimize pH-balance

~ controls the water’s electrical conductivity level

/ OXYGEN STABILIZATION

~ produces premium grade drinking water for bottling

~ produces medical grade water

~ stabilizes oxygen to highly concentrated levels

/ NUTRIENT ENRICHMENT

~ produces nutrient-formulated oxygen water

~ enriches water with a configurable nutrient balance

~ produces irrigation water for agriculture

~ produces tank water for aquaponics

FUEL PRODUCTION

~ synthesized from the system’s reformed aqueous solution

~ produces carbon-free, non-toxic hydrogen-based fuel

~ provides fuel for the system’s turbine in the power unit

~ produces surplus fuel for distribution to consumer markets

/ SYNTHESIS

~ formulated as aqueous liquid plasma of serum components

~ formulated to combust only while under pressure

~ formulated with a configurable heat energy density

~ classifiable as biofuel in a co-generation bottoming cycle

~ compatible and miscible with Diesel fuel or Jet fuel

~ compatible in combustors using liquid injector retrofits

/ HYDROGEN STABILIZATION

~ prepares hydrogen to comprise the fuel’s energy carrier

/ OXYGEN STABILIZATION

~ prepares oxygen to comprise the fuel’s combustion oxidant

POWER PRODUCTION

~ production of electrical power for system

~ production of surplus power for distribution to power grid

~ turbine, generator & transformer comprise the “power unit”

~ scalable to multiple gigawatt capacity

~ configurable and compliant to any global standard

~ configurable for baseload and peak-power

~ immune to electromagnetic field (EMF) interference

~ immune to electromagnetic pulse (EMP) damage

/ TURBINE OPERATION

~ operates using the system’s produced fuel

~ operates using a recirculative, self-cooled closed-cycle

~ recycles water vapor and noise emissions by recirculation

/ GENERATOR OPERATION

~ analyzes transmission line dynamics in real-time

~ uses transmission line feedback signal for auto-adjustment

~ synchronizes to grid or networks electronically

~ balances, follows and matches electrical grid load

~ responds instantly to large swings of electrical loads

~ powers-up in minutes with or without load (black start)

/ TRANSFORMER OPERATION

~ converts generator output to 3-phase 50/60Hz AC

~ recirculates power with generator in a closed cycle until loaded

GAS PROCESSING

~ manages gases used by the system’s fuel & water production

/ HYDROGEN DERIVATION

~ provides hydrogen to be fixed into the produced fuel

/ OXYGEN DERIVATION

~ provides oxygen to be fixed into the produced water & fuel

MATERIALS PRODUCTION (optional)

~ produces materials from the system’s aqueous solution

/ CONSTITUENT EXTRACTION

~ isolates, extracts and accumulates selected materials (e.g., separates salt as an isolate from seawater or brine)

/ MATERIALS FORMULATION

~ formulates configurable molecular products (e.g., produces liquid carbon from high-carbon intakes)

COMPARISON – LANGENBURG VS TYPICAL METHOD

ELECTRICAL CONSUMER GRID POWER

BY Langenburg-proprietary regenerative quantum-electrodynamic generator, connected by shaft to a closed-cycle hydrogen turbine; the output converter for 3-phase AC output compatibility to any global standard.

TYPICAL METHODS

magnetic induction generator

gas turbine

jet turbine

steam turbine

wind turbine

diesel piston engine

solar voltaic

thermonuclear

hydroelectric dam

SYNTHETIC FUELS

BY Langenburg-proprietary direct wastewater solids conversion quantum biohydrodynamics and quantum electro-chemical

molecular formulation.

TYPICAL METHODS

Fischer-Tropsch

methanol-to-gasoline

direct-coal liquefaction

HYDROGEN &

HYDROGEN-BASED SYNTHETIC FUELS

BY Langenburg-proprietary direct wastewater solids conversion to, and stabilization into an aqueous solution at ambient temperature, by quantum biohydrodynamics – Langenburg hydrogen-based liquid carbon/emission-free fuels qualify as the purest form of Green Hydrogen.

TYPICAL METHODS

hydrolysis & thermolysis

steam reformation from hydrocarbons

byproduct of chlor-alkali process

cryogenic hydrogen

hydrogen fuel-cell

OCEAN

SEAWATER DESALINATION

BY Langenburg-proprietary water separation using quantum hydrodyamics processing. Salts are isolated and collected as medical-grade quality, or converted to fuel used to operate the system. Material components of the intake water can be isolated and collected.

TYPICAL METHODS

boiling / vacuum / membrane distillation

ion exchange

electrodialysis reversal (EDR)

forward / reverse osmosis

freezing / geothermal desalination

solar & multiple-effect humidification

high-grade water recycling

seawater greenhouse

MUNICIPAL TAP, POTABLE & PREMIUM DRINKING (BOTTLE GRADE) WATER

BY Langenburg-proprietary water separation using quantum hydrodynamics; mineral supplementation; pH balancing; microclustering; oxygen enrichment/stabilization; nutrient enrichment (agricultural irrigation applications.

TYPICAL METHODS

sequencing batch reactor

membrane bioreactor

moving-bed biofilm reactor

microfiltration & ultrafiltration

ion-exchange & deionization

activated carbon/charcoal tower

ultraviolet light treatment

ultraviolet radiative ozonization

boiling & distillation

reverse osmosis

chlorination & iodine treatment

solar water disinfection (SODIS)

WASTE REMEDIATION, RECYCLING &

DESTRUCTION

BY Langenburg-proprietary direct non-thermal plasma reduction and conversion using quantum biohydrodyamics.

TYPICAL METHODS

conventional sorted recycling

incineration

chemical agents

oxidation reduction

landfills (degradation / soil capping)

wastewater holding ponds /degradation

activated carbon

bioreactors / biowall / cometabolics

electrokinetics

groundwater circulating wells

groundwater pump & treat

pH control

monitored natural attenuation

multi-phase extraction

permeable reactive barrier

phyto-technologies

soil vapor extraction & washing

solvent extraction

plasma arc

microfiltration & ultrafiltration

ion-exchange & deionization

activated carbon/charcoal tower

UV light treatment & ozonization

boiling & distillation

reverse osmosis

chlorination & iodine treatment

solar water disinfection (SODIS)

more...

PROJECT EXHIBITS

LANGENBURG HALF-GW WASTE-TO-ENERGY &

MUNICIPAL WATER PURIFICATION PLANT

COLUMBIA RIVER :: LAKE UMATILLA :: PORT OF MORROW :: CITY OF BOARDMAN, OR

CONSTRUCTION PHOTOS

Located adjacent to The Port of Morrow, this project will be the first truly self-sustaining, completely renewable system to convert waste into municipal water and energy. The core structure has been constructed as seen in the below map reference.

This landmark power plant will operate with the following features and capacity:

BANK 1: 300 megawatts baseload/peak power;

BANK 2: 200 megawatts baseload power;

10 x 50 MW Langenburg-proprietary power units;

electrical load-following and 1-minute black start (without external hydraulic starter);

separation of pure water component from raw industrial liquid waste for municipal tap supply;

residual liquid waste concentrate conversion to non-carbon synthetic hydrogen-based fuel;

zero emissions from the turbines;

all of the waste is converted without any residual.

The liquid waste intake capacity target is 6-10 million gallons per day. Over 95% of the water content is separated from the intake stream, then treated and purified as municipal tap supply water. All remaining component byproducts from the intake are converted to non-carbon fuel used to operate an emission-free Langenburg-proprietary closed-cycle regenerative turbine. Each of the turbines are connected to Langenburg-proprietary regenerative quantum-electrodynamic power generators collectively operating at 500 MW baseload capacity, with standby excess of 50-100 MW of peak capacity. A major fraction of the plant’s capacity is also available for load-balancing. The power will be supplied local industrial users including food production and online web service farms,

as well as electrical power supply for the consumer grid.

The power plant is designed to accommodate gatherings, conferences and tours.

The below image shows the piping connection between the wastewater lagoon's pump-house, and the Langenburg waste-to-energy facility. 100% of the wastewater is converted to potable water and electrical grid power.

LOCATION OF CONSTRUCTION SITE

ULTRA-COMPACT SYSTEM

FOR WATER SEPARATION FROM WASTE, AND

WASTE CONVERSION TO ENERGY

APPLICATION: MULTI-PURPOSE INDUSTRIAL CURRENTLY DEPLOYED AT

THE LANGENBURG'S OPERATIONAL FACILITY IN CORDELE GEORGIA

CONSTRUCTION PHOTOS

The above compact system shown is installed on a 2-ton flatbed truck, enclosed within 1200 cubic feet container

with the following capabilities:

water isolation, treatment and purification;

material-to-energy conversion;

complete material destruction;

carbon-free fuel synthesis.

This example Langenburg system can be used as a baseline for evaluation and application scaling purposes. Over 95% of the water content is separated from the intake stream averaging a million gal/day. The separated water is purified as potable or as premium bottling water. The remaining component byproducts from the intake are converted to non-carbon fuel used to operate an external power generation set of at least 600 MW capacity.

External intake and product outflow holding tanks and pumps are added to realize the full throughput conversion capacity.

After completing its purpose for high-volume industrial food processing, it will then be adapted convert industrial wastewater sourced from three large holding ponds located near the Langenburg 500 MW Waste-to-Energy Plant near The Port of Morrow in Boardman, Oregon. Local industries producing the wastewater will benefit by the increased production made possible by the Langenburg's rapid processing that would otherwise limit their operations.

WASTE-TO-ENERGY, WATER SEPARATION, &

STEAM-TURBINE POWER GENERATION FOR GRID

A LANGENBURG FACILITY IN CORDELE, GEORGIA OPERATING SINCE 2019

CURRENTLY IN MID-PHASE DEVELOPMENT

OVERVIEW OF OPERATIONAL FACILITY

SEE MORE ABOUT THIS FACILITY IN THE "VIDEOS" MENU

Highlighted in the below map, is the location of a Langenburg client project operating since 2019 in Cordele, Georgia USA. Langenburg's core tech solution has been integrated with a mixed recycling and ethanol production facility that is operated by Synergy Solutions of Crisp County. One of Synergy's many operations is collection of beverage industry waste comprising various soft-drinks, brews, spirits and liquors. The recovered liquid is mixed and fermented in large holding tanks as a rebrew. The produced ethanol is sold to the petrochemical industry as E85 gasoline supplement. Synergy's website is: www.synergycrispcounty.com .

LANGENBURG PHASE-1 UPGRADES

separate water from liquid waste

In phase-1, Langenburg system components are utilized to separate the pure-water component from re-brewed beverage waste for production of bottling-grade drinking water. The Synergy facility collects expired and contaminated beverages, crushes the containers and recycles the packaging. Volatile ethanol is heat-distilled from the heavier fraction of the re-brew before processing by Langenburg system components.

LANGENBURG PHASE-2 UPGRADES

convert residual waste concentrate to fuel

Phase-2 implements the Langenburg Core Tech Solution™ to produce non-carbon fuel by converting residual concentrates leftover after from the water separation process. Langenburg proprietary fuel replaces Diesel as the heat source used by boilers, providing the heat source for a value-added distillation process without pollutive emissions. Because the fuel is produced on-site, fuel delivery cost is eliminated. Because the fuel is produced exclusively from waste, former use and cost of Diesel becomes obsolete. Langenburg upgrades will optimize the business model, while extending performance

and capacity far beyond any conventional process.

LANGENBURG PHASE-3 UPGRADES

use produced fuel to generate power

The final phase-3 involves use of the excess boiler steam from the distillation process to drive a steam-turbine for power generation. The power unit comprises a conventional steam-turbine and Langenburg-proprietary quantum-electrodynamic generator. Steam output from the boilers is extended by using Langenburg-proprietary nozzles and Langenburg-proprietary non-carbon fuel. Generator output is converted to standard 60Hz alternating current by use of a Langenburg-proprietary AC Converter. The facility is positioned to transmit 30-50 MW of baseload power to a substation located 3/4-mile away, for transmission onto the consumer power grid.

FACILITY TOURS

Operations at this facility have recently been available for guided tours to view progress of the phase-2 upgrades. Invitations for tours are available to parties that have signed the Langenburg NDA with submission of a letter of interest and whom are actively pursing project-based engagement according to the Langenburg Company Policy (see guide on "proposals" menu of this website). All tours are arranged exclusively through Langenburg USA headquarters.

SEE MORE ABOUT THIS FACILITY IN THE "VIDEOS" MENU

LOCATION OF LANGENGBURG OPERATIONAL FACILITY

Illustrations show the architectural visualization of the concept for Langenburg's future flagship power plant, visitor center and research facility. The GW-PowerCentris™ is one of many elements of the Langenburg-Columbia development project. 3D-archviz conceptioneering models of this internal project are presented in this exhibit, and in the "About Langenburg" video, shown in the "VIDEO" menu of this website.

The facility's iconic signature design is derived from the coordinate plot of a mathematical function describing a quantum

function of photonic interaction.

The emission-free plant will operate at nearly 1 GW (1000 megawatts) using Langenburg's proprietary carbon/emission-free fuel made exclusively from water. It is anticipated that the input will eventually become wastewater residual from agricultural-industrial production plants, which enables the local industries to increase their output capacities to unprecedented levels. The six Langenburg-proprietary generators of the PowerCenter™ are driven by Langenburg-proprietary closed-cycle regenerative hydrogen turbines.

The power plant will be surrounded by cascading water pools to carry the theme of The Power of Water™, encompassed by a quasi-circular structure comprising research facilities.

About 8 miles eastward near the Port of Morrow in Boardman Oregon, is Langenburg's Half-GW waste-to-energy plant currently under construction, shown above in the "PROJECT EXHIBITS" menu on this website.

LANGENBURG GIGAWATT POWER-CENTRIS™

FUTURE FLAGSHIP WASTE-2-ENERGY & WATERWORKS PLAN,T

VISITOR CENTER AND HOME OF LANGENBURG RESEARCH

A LANGENBURG-COLUMBIA DEVELOPMENT PROJECT